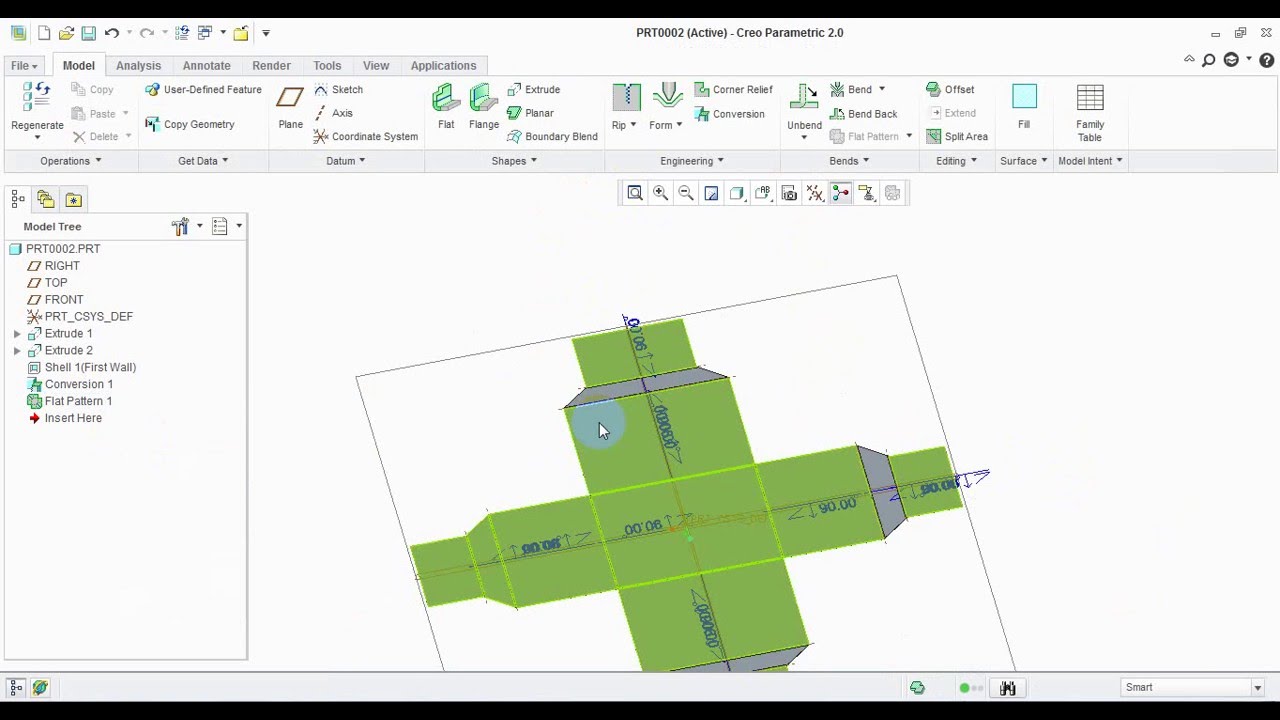

As sheet metal parts are flattened or formed if you start with a flat state pro sheetmetal utilizes a y factor to allow for the fact that metal is elastic and stretches as it bends.

Pro e creo sheet metal tutorial.

One way to do it of course it is to convert it as a surface copy surfaces convert to sheet metal and use offset tool.

Product designers and engineers will be more productive enabling better data sharing and design reviews with customers and suppliers and preventing unforeseen service and manufacturing issues.

Built on the legacy of pro engineer cocreate and productview creo is a family of design software which will help companies unlock potential within their organizations.

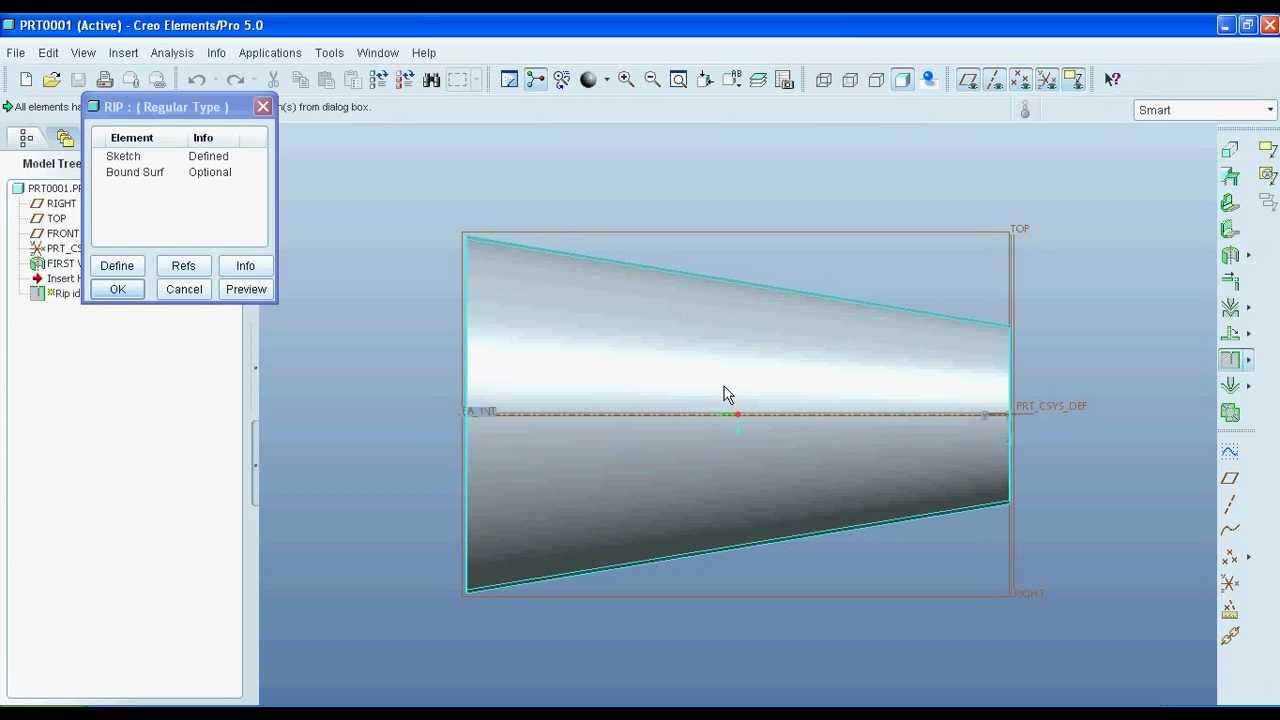

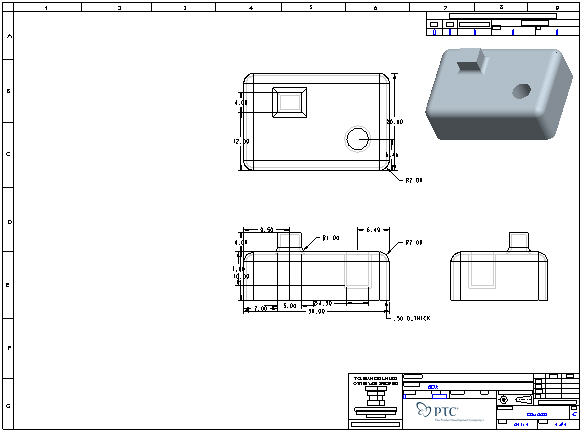

Draw your chassis design in standard pro e as a solid brick see figure 1.

But then the inner surface between the roller features leaves out.

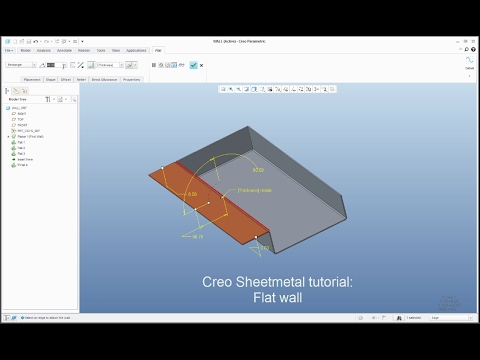

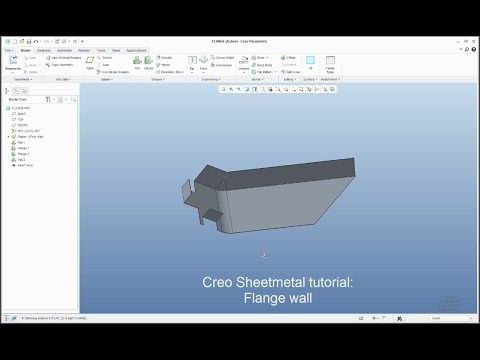

Creo sheet metal tutorial sheet metal bracket 1 in creo parametric duration.

The path to creo.

For this example to the part has designed roller forming.

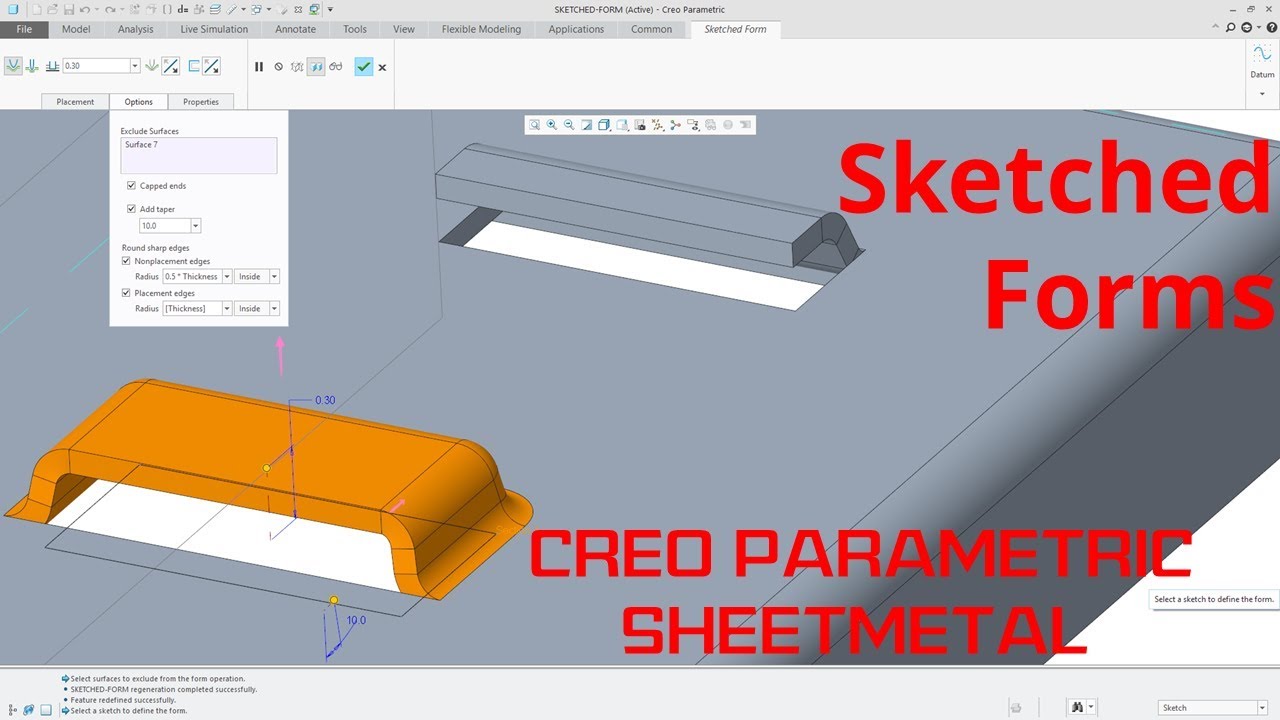

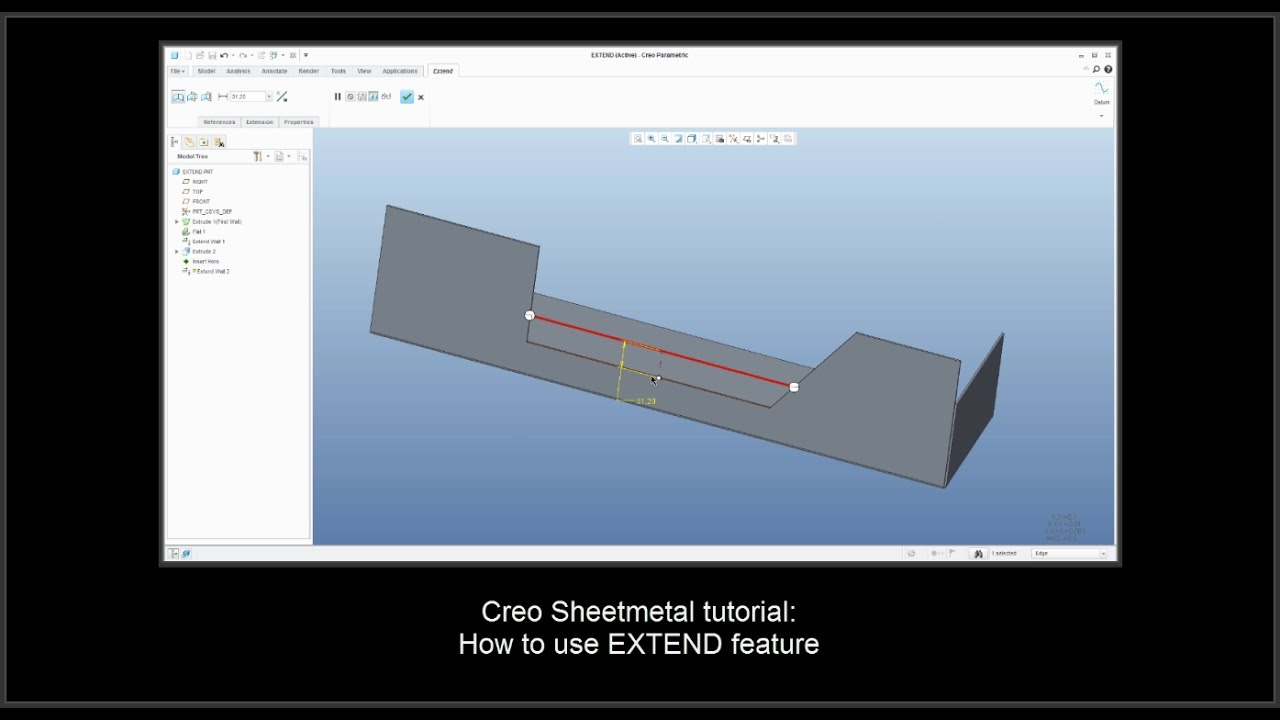

This comprehensive suite of creo sheet metal design tools helps users create features such as walls bends punches notches forms and relief features.

Creo does not recognize the part when trying to convert it to sheet metal as picking driving surface.

Learn more pro program training.

Sheet metal in creo tutorial 1 planer command in creo parametric.

Remember to make sensible choices of datum plane positions you will be pleased you did later.

Emphasis can be placed on your specific creo pro e mechanism interests.

Select under applications the sheet metal option and from the smt convert menu that appears choose shell.

Learn more cable harness design week two.